Robotics

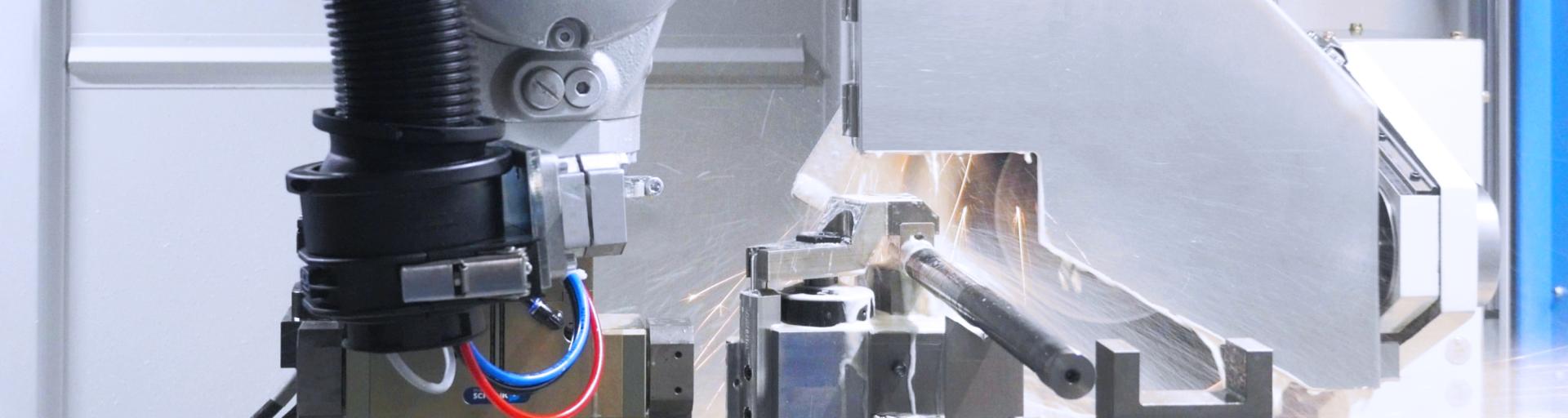

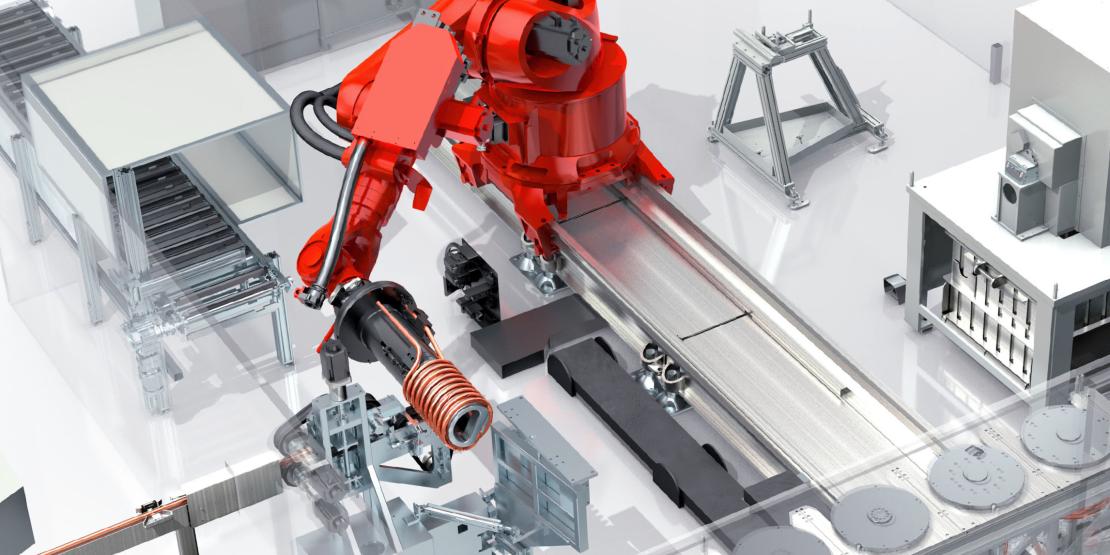

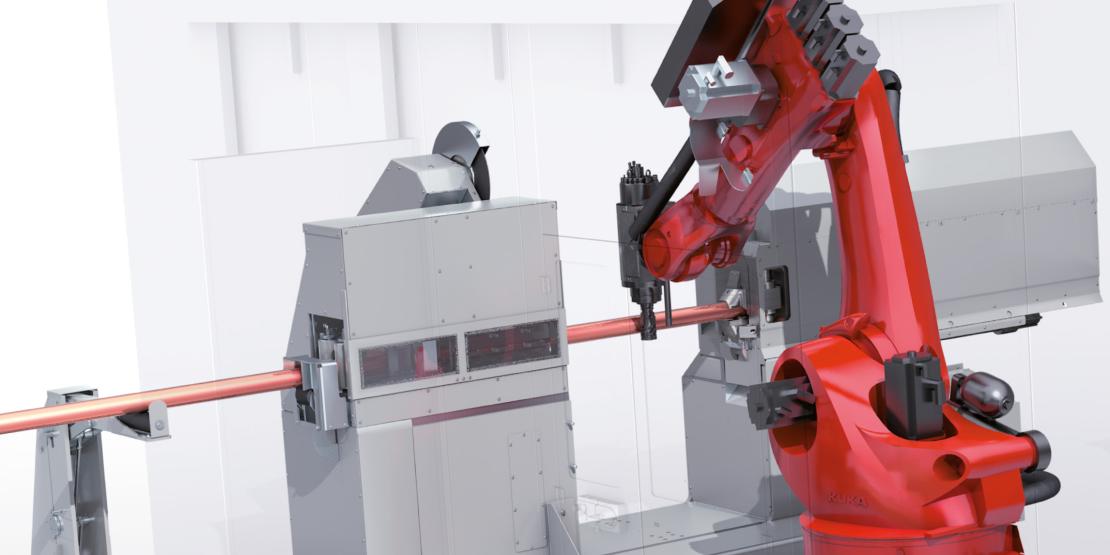

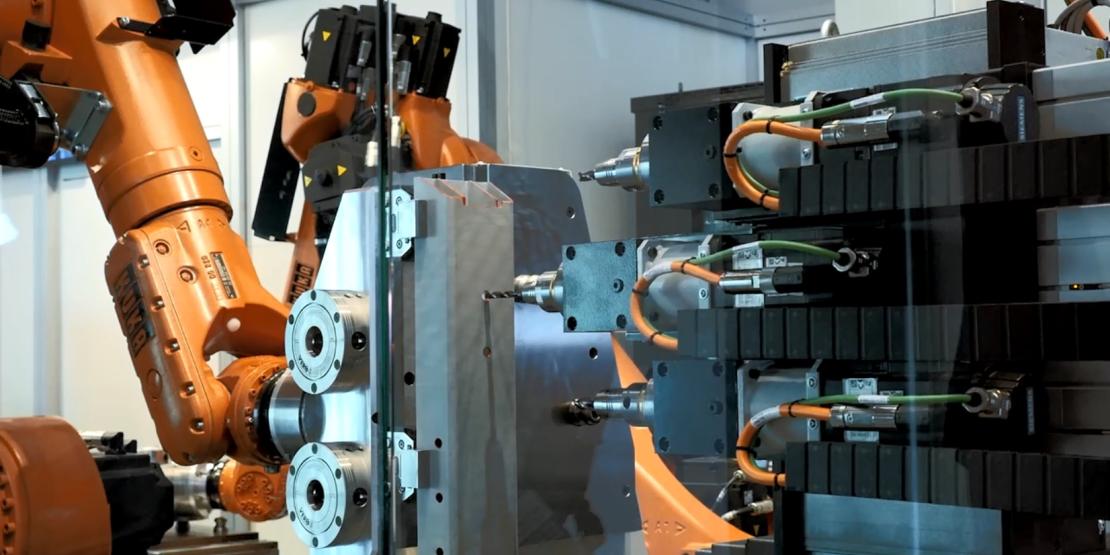

We offer the opportunity to precisely machine geometrically complex workpieces with industrial robots. During the machining, the robot is supported by additional guiding systems or is locked in case of the highest precision requirements.

Especially for large workpieces with free form surface and tight production tolerances our machine concept is an efficient and cost-effective alternative to a normal machining centre. Via "Run MyRobot" the robot is fully integrated into the CNC control. Neither operators nor programmers need any robot programming knowledge.

Vores produkt sortiment

Kort robotics fortalt.

Wieland Anlagentechnik

Dette er vores Wieland Anlagentechnik produktsortiment.

Kontaktpersoner

Kontakt – vores experter robotics

![]() Tobias Ziesel

Tobias Ziesel

Sales & Marketing

Wieland Anlagentechnik

+49 731 944 1822

Send e-mail

Kender du allerede dine søge kriterier? Benyt vores fuld tekst søgning og få en liste med alle relevante resultater.