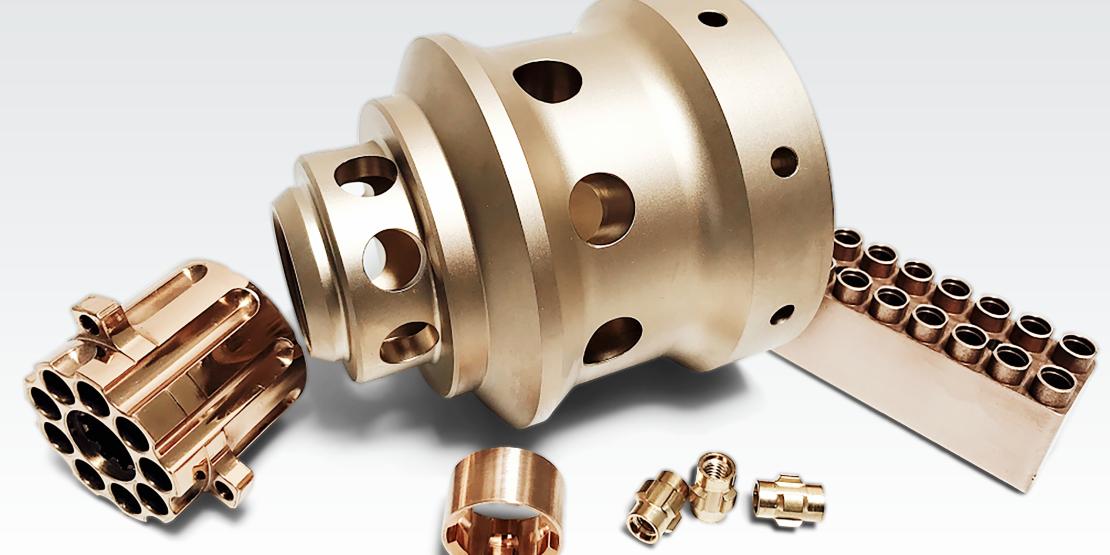

Sæt bevægelsen i spil: glidelejer fra Wieland. Lejerne tjener adskillige formål, og de kan findes i teknisk sofistikerede forbrændingsmotorer som stempel- og plejlstangsbøsninger eller vippearmsstifter. Wieland glidelejer bruges også i lejer til moderne aksel- og bremsesystemer, transmissioner, differentialer og hydraulikpumper samt i oscillerende elementer såsom bomme eller gribersystemer på entreprenør- og landbrugsmaskiner.

Produkterne fremstilles i forskellige versioner efter dine ønsker. I samarbejde med dig arbejder vi specifikt på nye udgaver og videreudvikling af vores produkter. Vi lægger stor vægt på en moderne og økonomisk produktion.

Vores produkt sortiment

Kort fortalt.

Vores komplette produktsortiment

For at vise produkt sortimentet på en bestemt lokation, vælg venligst hvilken lokation:

Kontaktpersoner

Kontakt – vores experter

![]() Volker Voggeser

Volker Voggeser

Vice President I BU Engineered Products

Wieland-Werke AG

+49 731 944-2135

Send e-mail

Kender du allerede dine søge kriterier? Benyt vores fuld tekst søgning og få en liste med alle relevante resultater.