Data sheet

Wieland-S40

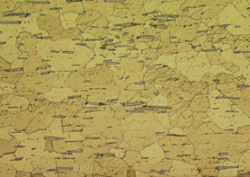

Wieland-S40 By adding Al, Mn and Si, special brass with very high load capacity, good corrosion resistance and good sliding friction coefficient.

Hardened shafts are recommended for higher loads. Used wherever high forces are combined with shocks, e.g. excavator joints, steering knuckles, etc. Furthermore in slip clutches, as valve guides in car engines and power lift bearings in tractors.

Composition (standard values)

Cu 58 %

Mn 2 %

Al 1.5 %

Pb 0.7 %

Si 0.5%

Zn balance

Material designation

Wieland S40

EN 12449 : 1999

Max. load

Oscillating bearings up to 120 MPa

Types available

Machined bushings

| OD up to 200 mm | |

| Wall thickness depending on OD | 2 to 30 mm |

| Density [g/cm3] | 8.1 |

| Coefficient of thermal extension (20 - 300 °C) [10-6/K] | 20.4 |

| Thermal conductivity[W/m*K] | 63 |

| Modulus of elasticity (20 °C) [GPa] | 93 |

| Temper | |

| Hardness [HB/HRB] | 155 / 85 |

| Tensile strength Rm [MPa] | 640 |

| 0.2 %-proof stress Rp0.2 [MPa] | 345 |

| Elongation A5 [%] | 18 |

1 MPa = 1 N/mm2