The highest efficiencies with the lowest refrigerant charge – Over 10000 kw capacity available

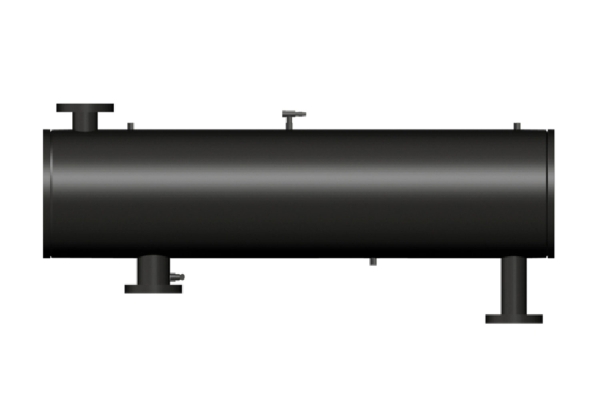

Complete range of standard flooded evaporators

With integrated internal heat exchange good for guaranteeing high superheat and subcooling

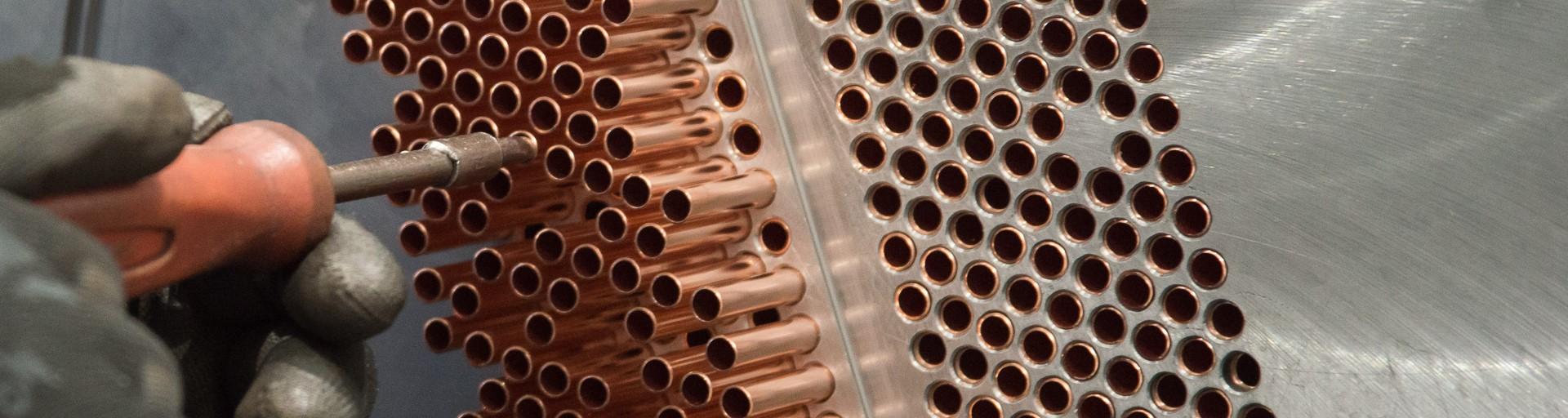

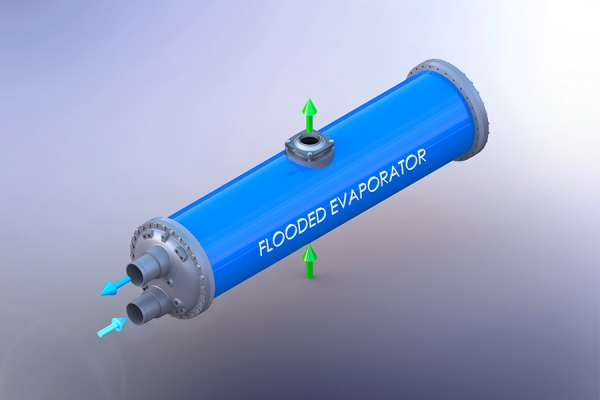

In flooded evaporators, the refrigerant evaporates outside the pipes. The state-of-the-art heat exchange pipes, internally and externally finned, together with the distribution of refrigerant - both at the evaporator inlet and at the suction - guarantee the achievement of very high efficiencies.

Beyond this advantage, compared to dry expansion evaporators, the partialization of the load can be lower. Through the use of jet pumps (supplied as an option) it is possible to use the flooded / spray evaporators also for oil systems. The removal of the caps allows the cleaning of the bundle and therefore the preservation of efficiency over time.

Flooded evaporator

- Thermal powers from 50 kW up to 10 MW.

- Temperature approach down to 0.5K.

- Up to three refrigerant circuits; the tubes are expanded into intermediate tube plates, guaranteeing the seal between the circuits.

- Different configurations possible with 1, 2, 3 or 4 water passages.

- Absence of liquid entrainment thanks to the dedicated design of gas distributors for suction.

- Available optionals: elastomeric foam insulation, electric heaters, jet pump, Victaulic or flanged water connections, water filters.

- Regulation by means of refrigerant level control or subcooling temperature (liquid line).

Flooded evaporator 406

Flooded evaporator 508

Flooded evaporator 610

Flooded evaporator 711

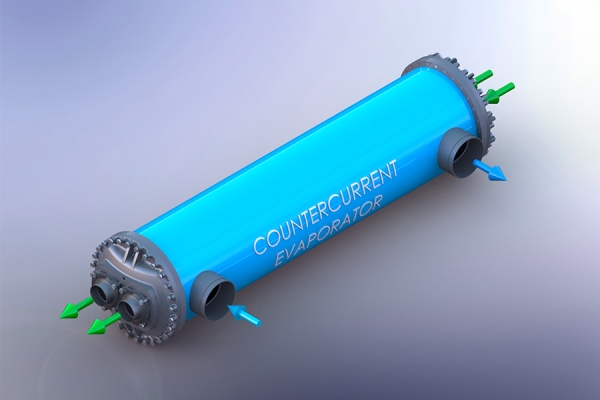

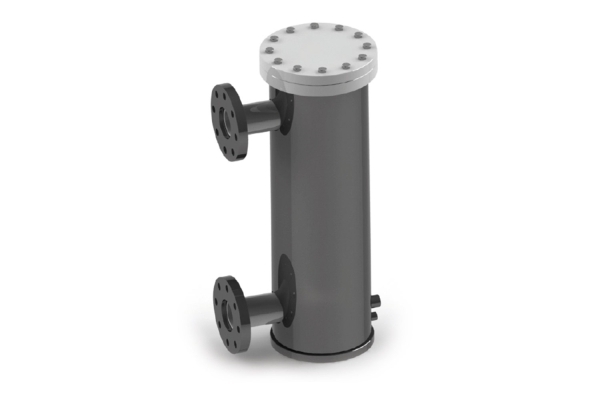

Spray technology

Initially used for compact evaporators, the use of spray technology was subsequently implemented on S&T flooded evaporators.

Depending on the geometry, the saving of the refrigerant charge ranges from 50% up to 70%, compared to a flooded solution of the same size and performance.

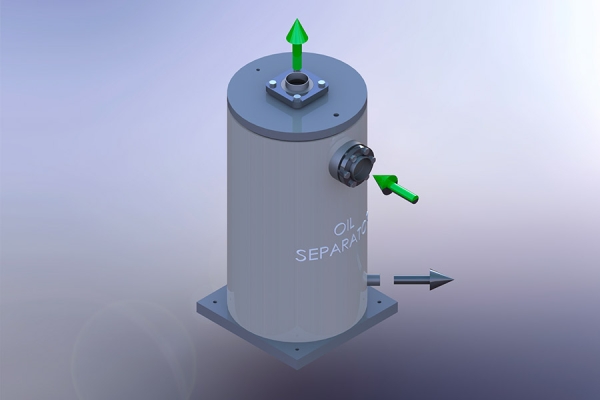

The low level of the refrigerant allows it to be used easily even with screw compressors, as the oil concentration is relegated to a smaller amount of liquid and therefore easier to tap through the jet pumps.

The non-flooded area of the bundle also allows the spray evaporator to be used as a liquid receiver, as it can accommodate tens of kg of extra refrigerant without undergoing changes in efficiency.

The experience gained has made it possible to apply spray technology even to larger models. Environmental regulations impose increasingly stringent limits therefore reducing the amount of refrigerant is a big advantage, especially for large volumes.

To date, the revision of the project is available with the ESWT spray top version: the liquid refrigerant inlet positioned at 45 ° above the center line saves an additional charge of refrigerant and reduces the space required at the base of the exchanger.

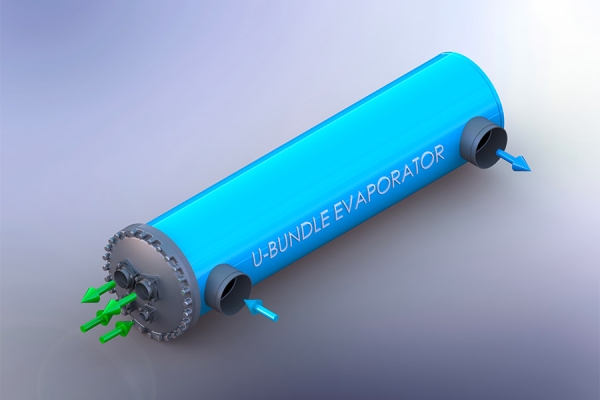

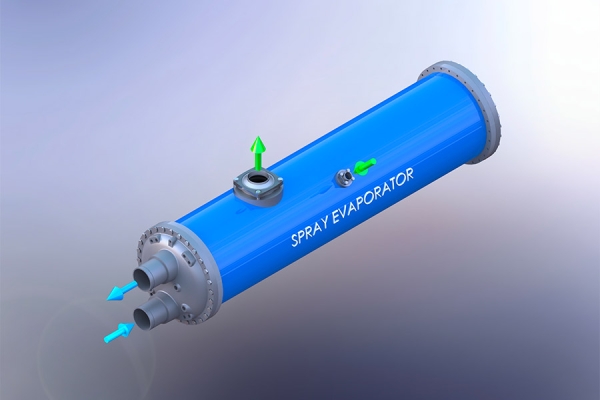

Spray evaporator

- Refrigerant charge down to 70% less compared to an equivalent flooded solutio.

- Version with liquid inlet from above (top feeding), optimizing the lower spaces.

- Performances, geometries and configurations such as flooded evaporators.

- High efficiencies and temperature approaches < 0.5K can be achieved with spray technology too!

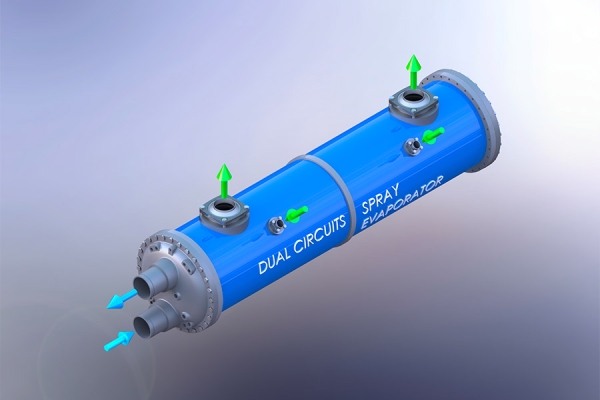

Dual circuit spray evaporator

- Two independent cooling circuits to better track changes in cooling demand and increase system reliability.

- In case of circuit failure, the side that has remained in operation can still provide sufficient cooling until it is restored.

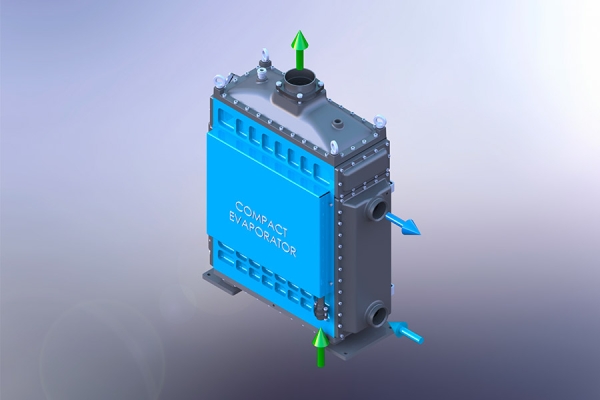

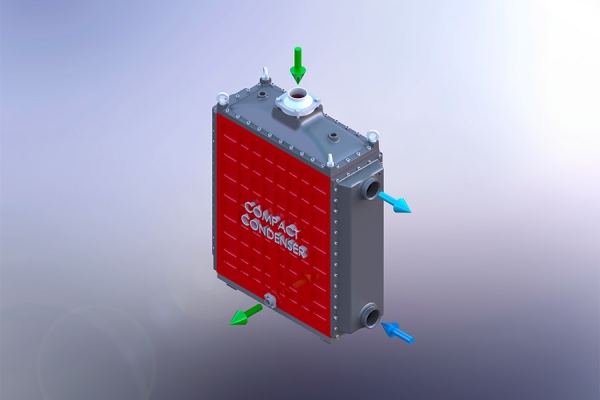

Compact CSF and CCF heat exchangers

The idea of a water-condensed refrigeration unit, compact, efficient, reliable and easy to maintain, found concreteness with the compact CSF and CCF heat exchangers.

The modular configuration (for redundancy or for capacity increase), the small footprint suitable for lifting in industrial goods lifts, the shell iron casing and the hinged caps to be able to inspect and clean the tube bundle are just some of the strengths of the our compact.

Usable with both oil-free and screw compressors, the compact heat exchangers - tested for a design pressure of 18 bar - can be used with HFC, HFO and propane refrigerants.

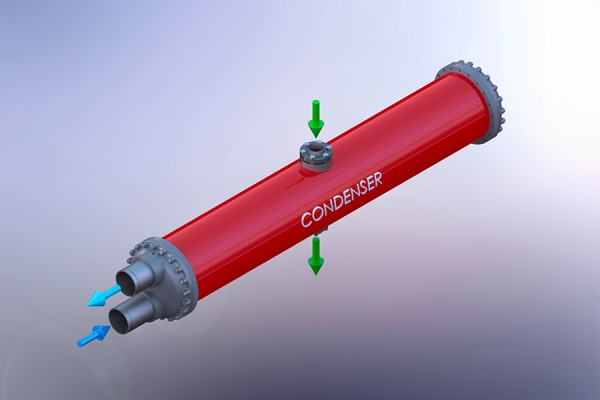

Compact flooded evaporators and condensers

- Ideal for reduced spaces: compact volume 1300x1020x383 mm.

- Ideal for naval installations (without roll and pitching problems).

- Modular.

- 1K approach temperature with 300kW of cooling capacity.

- State-of-the-art high-efficiency tubes.

- Built-in intermediate exchanger to achieve additional subcooling at liquid line and suction superheat.

- Very low refrigerant charge required (75 kg for an oil-free chiller consisting of compact evaporator and condens).

- Possibility of having any number of water outlets as needed, according to the required ΔT in/out.

- Cleaning the tube bundle on the water side is possible WITHOUT the need to disassemble the water system, thanks to the hinged caps.

You need more information? Contact us!

+39 0773 4401

Send e-mail

![]() Franco Provenziani

Franco Provenziani