Data sheet

Wieland-SB7

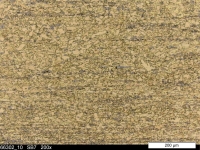

Wieland-SB7 is a nickel-containing special brass with hard, wear resistant manganese silicides. It has been specially developed for the function of the freely running slipper shoe. Its high 0.2% proof stress makes it particularly ductile and allows it to be easily bent around the joint of the steel piston. Wieland-SB7 can also be used for other antifriction elements.

Composition (standard values)

Cu 57 %

Mn 2.2 %

Ni 2.0 %

Si 1.1 %

Pb 0.7 %

Zn balance

Material designation

Wieland SB7

DIN/ISO/EN not standardized

Max. load

Suitable for operating pressure of min. 450 bar

Types available

Machined slipper shoes

| Density [g/cm3] | 8.3 |

| Coefficient of thermal expansion (20 - 300 °C) [10-6/K] | 20.5 |

| Thermal conductivity [W/m*K] | 85 |

| Modulus of elasticity (20 °C) [GPa] | 100 |

| Temper | |

| Hardness [HB/HRB] | 150 (HRB 83) |

| Tensile strength Rm [MPa] | 530 |

| 0.2 %-proof stress Rp0.2 [MPa] | 350 |

| Elongation A5 [%] | 10 |

1 MPa = 1 N/mm2