Roller device for railway points

Maintenance-free, robust and failure-resistant

Austroroll sets international standards for maintenance-free roller devices for railroad turnouts with the consistent development of the „rolling instead of lubricating“ concept. Austroroll saves up to 25 liters of lubricant per year and point. Inefficient and labor-intensive slide chair lubrication is now a thing of the past. As well as being environmentally friendly, this also protects the superstructure and increases work safety for our customers.

Your benefits at a glance

- Optimizes the track availability

- The only permanent flexible roller system worldwide

- 100 % maintenance-free

- Amortization period less than 2 years

- Easy installation – also possible during train breaks

- Remains in the track during tamping, grinding or milling

- Personal service and installation training

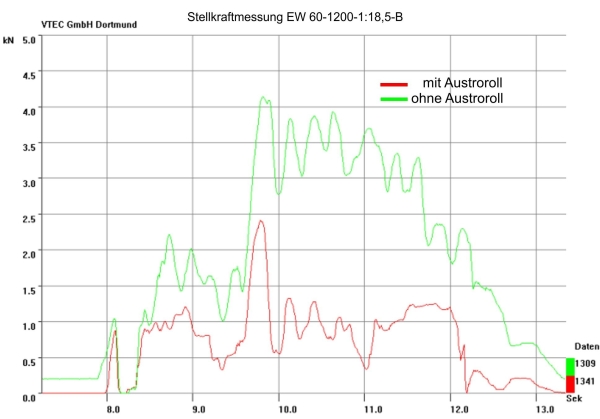

Wieland Austria GmbH's product, awarded the Innovation Prize of the Republic of Austria, ensures lubrication-free operation and a reduction of throwing resistance of up to 60% for all types of switches.

Video instructions

We now also support you online with our video instructions for the installation of Austroroll!

More than 30 years of experience

Up to 60 % reduction of throwing forces

Austroroll units in operation worldwide

Function of Austroroll in detail

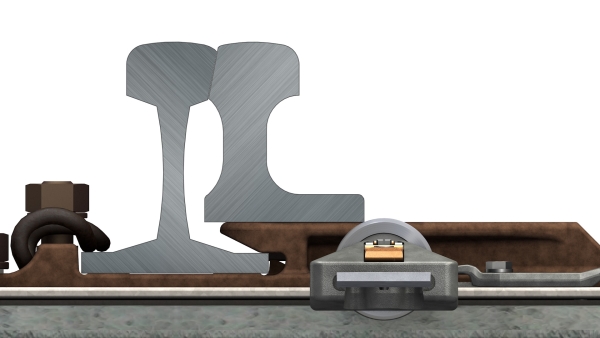

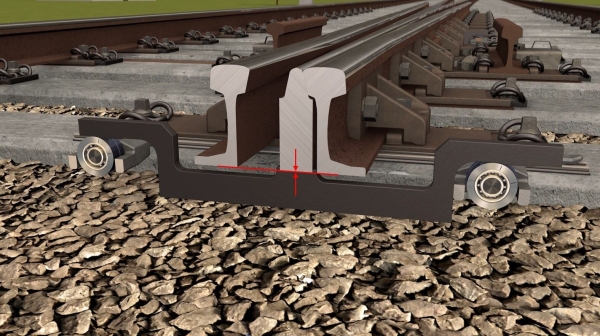

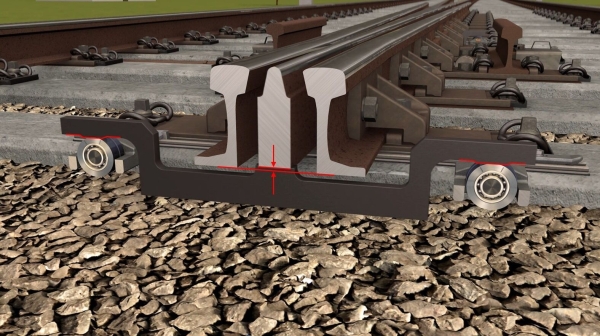

1. In the closed position the switch blade rests on the slide chair. The Austroroll device clamps the switch blade horizontally against the stock rail.

2. At the start of the switching operation the blade rolls on to the roller and is lifted off the slide chair. This means there is no sliding movement.

3. The switch blade rolls to its final position via the roller with a minimum of friction, and remains resting on the roller.

4. When it is time to reset the points, the blade rolls back to its original position on the slide chair, and is returned to the desired final position.

Product video

Austroroll® - The maintenance-free switch point roller

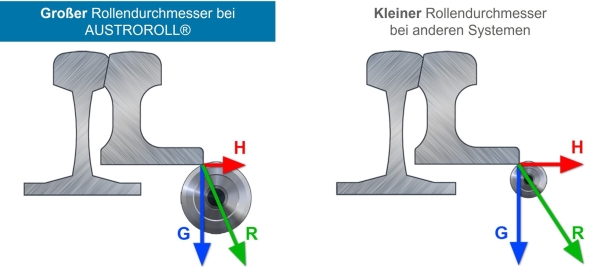

Advantage of Austroroll: large roller diameter

The large roller diameter makes it easier to raise the point blade, significantly reducing the required throwing force.

Austroroll reduces the throwing forces by up to 60%.

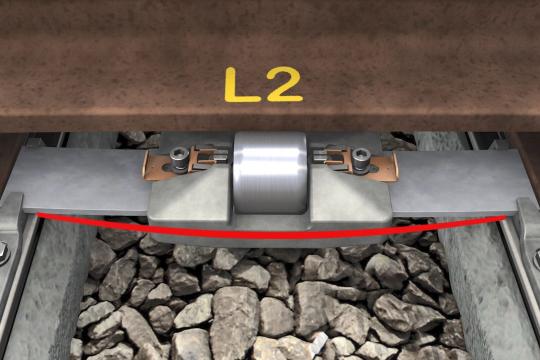

The only permanently elastically mounted roller system

Austroroll is equipped with appropriately dimensioned, hardened steel springs and surface protection. The flexible system and the position in the sleeper bay make Austroroll resistant to impacts, vibrations and other dynamic loads.

- Horizontal force component

The springs are pretensioned during assembly, ensuring that the points close tightly. The horizontal force component presses the point blade firmly against the stock rail.

- Roller bearing mountings

The fact that the roller contains dual roller bearings makes for long service life and consistently low friction levels.

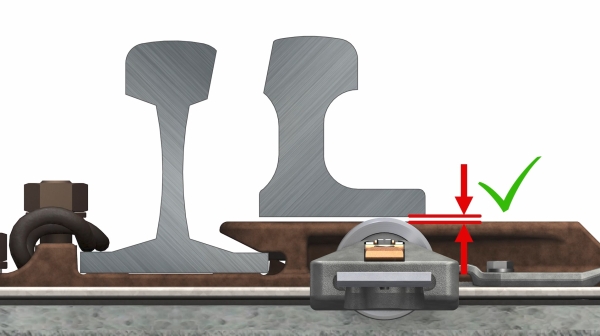

- Positioning

The location of the device between rather than on top of the sleepers leaves room for spring mounting, and prevents dirt, snow, ice, etc. from collecting and jamming the roller.

- Service life

Good design and high-quality materials mean that the mechanism has a long service life and will outlast the points.

- Pre-tensioning

The pre-tensioned springs ensure that the tongue rolls onto the roller right at the start of the switching operation and prevents any sliding on the slidechair

- Materials

The Austroroll components are made of corrosion resistant high-strength materials - ideal for harsh railway operating conditions, and capable of withstanding extreme temperature fluctuations, bad weather, wear and corrosion.

- Hardened and tempered steel springs with surface protection

- Surface coated roller and roller block

- Setting screws and other components made of special alloys

- Seals

The hermetic sealing of the bearings in the roller by three different, carefully matched systems makes Austroroll impervious to dirt, snow, water and other adverse factors.

- Installation

Austroroll is quick and easy to install in new and existing points. There is no need to exchange the slide chairs.

- Economic efficiency

A short amortization period - depending on the switch situation - of approx. 2 years as well as low installation costs and a long service life make Austroroll an economical solution.

- Tamping

Also the regular tamping of the ballast track as well as the grinding and milling of the track profile is trouble-free possible without any demounting of Austroroll.

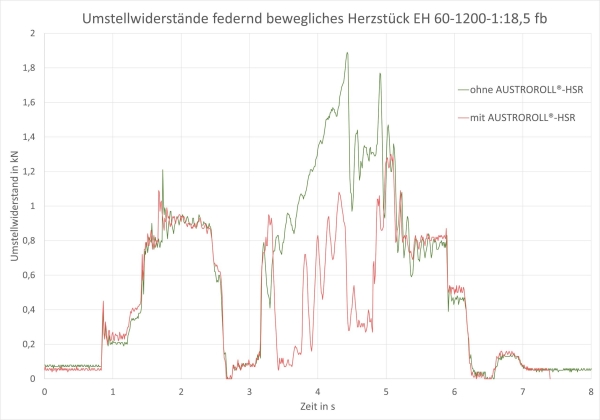

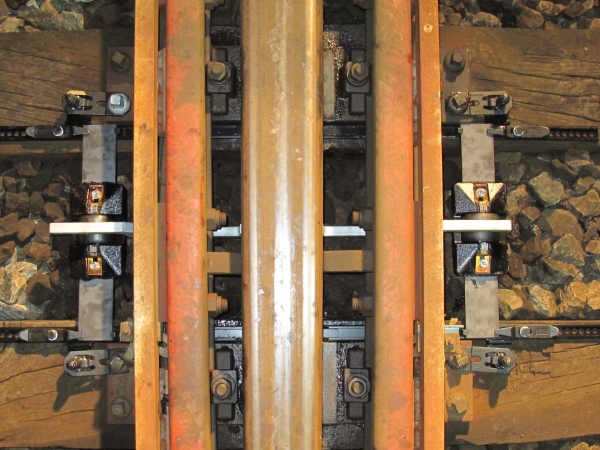

Austroroll MFR for spring-loaded moving frogs

The patented Austroroll movable frog roller (MFR) is a rolling device for frogs with moveable point. With the combination of Austroroll roller devices and the Austroroll frog rollers, it is for the first time possible to achieve completely lubrication-free points.

Product video

Austroroll® MFR - The maintenance-free roller device for frogs with a moveable point

The principle of functioning is similar to that of the proven Austroroll rolling device in the switch blade area. However, in the frog, the very cramped space conditions do not enable any direct installation of rollers at or under the moving frog point.

The function of lifting the frog during the setting procedure is assumed by a displacement bracket. This displacement bracket is attached under the frog and guided by two rollers mounted to the side of the wing rails. In its end position, the frog tip rests securely on the sliding chairs. Only at the start of the setting process the bracket lifts the frog tip, transports it to the opposite end position and replaces it there down again.

A lubrication of the slide plates is therefore no longer necessary.

Austroroll®-HSR significantly reduces the changeover resistance also in the frog area.

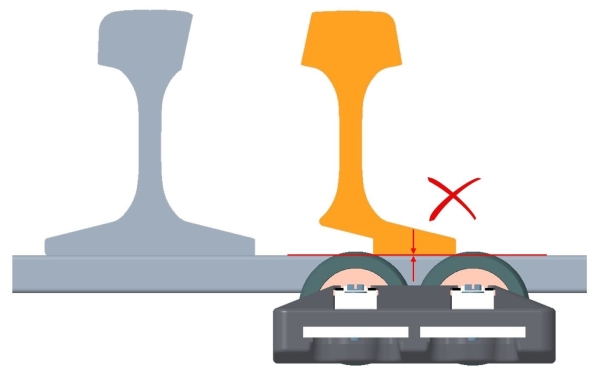

In some cases, tongue rails with particularly narrow “feet” are used - e.g. Bullhead or AREMA profiles. They would lower themselves between the rollers and therefore slide on the slidechairs.

With the newly developed Tri-Roll, however, this is no longer a problem. There is a small additional roller between the large rollers, which ensures that even narrow tongue rails can be transported on without friction. Thanks to the ingenious design, this special solution has no effect on the assembly process.

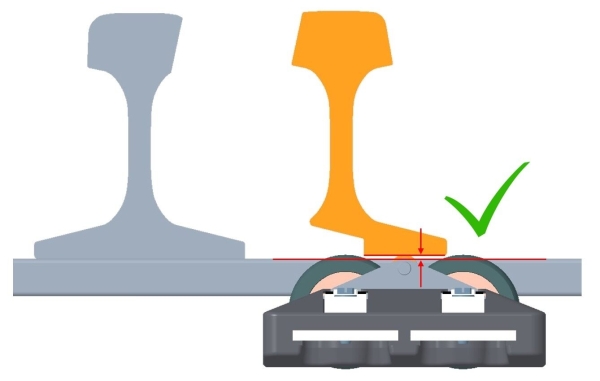

A photo of the use of a Tri-Roll is shown adjacent.

Installation examples

Austroroll® roller devices can withstand the most adverse environmental conditions and are extremely adaptable for use in a wide variety of superstructure situations.

Picture on the left: Austroroll® switch point rollers for BWG slidechairs

Austroroll® switch point roller under extreme contamination in a steel mill

Austroroll® switch point roller under extreme temperatures and weather conditions

Austroroll® switch point roller for new turnouts with plate solution

Austroroll® switch point roller for retrofitting on concrete sleepers

Austroroll® switch point roller for retrofitting on wooden sleepers

Austroroll® switch point roller for retrofitting on wooden sleepers with special mounting

Austroroll® switch point roller for BWG slidechairs

Austroroll® switch point roller for elastic support of ribbed plates (ERL30)

Austroroll® switch point roller for steel sleepers

Austroroll® moveable frog roller for new turnouts with plate solution

Austroroll® moveable frog roller for retrofitting on concrete sleepers

Austroroll® moveable frog roller for retrofitting on wooden sleepers

Austroroll® moveable frog roller for retrofitting on concrete sleepers with composite anchor fastening

Austroroll® moveable frog roller for retrofitting on concrete sleepers with composite anchor fastening and special mounting

Contact

Our experts for rolling device for railroad switches

Robert Kollouch, BU Engineered Products | Head of Railway Engineering

+43 2256 81145 236 austroroll@wieland.com

Our range of products

Our roller device for railway points at a glance.

Our complete product range

To show the product portfolio of a specific location, please select the company:

Already know your search term? Then go ahead and use our full text search. You will get a list of all relevant results.