Finned tubes

Optimized surfaces for a highly efficient heat transfer

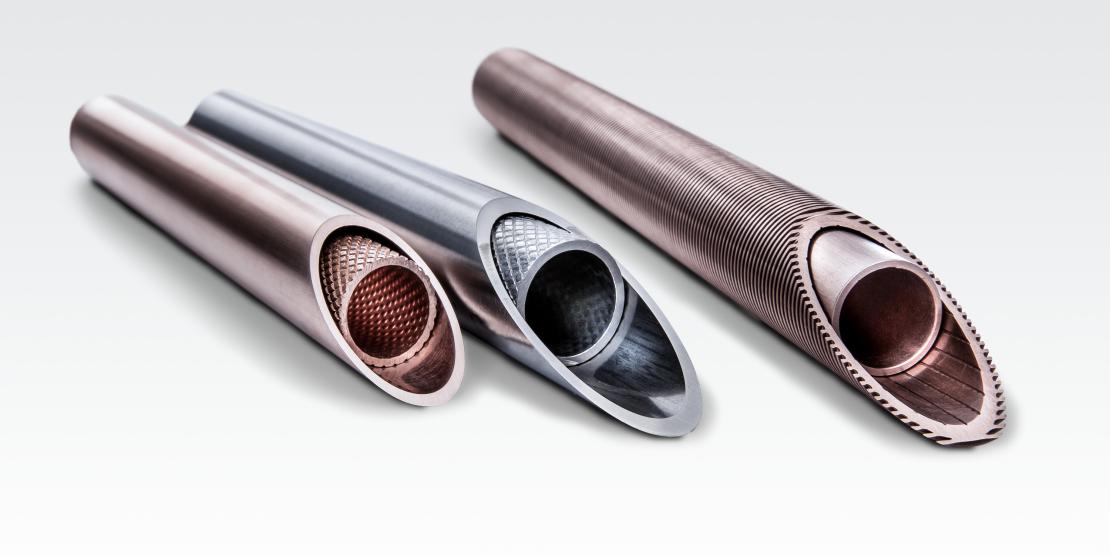

Finned tubes made by Wieland Thermal Solutions are produced from plain tubes that have undergone a forming process. They serve as components in highly efficient, compact, yet extremely stable heat exchangers. Tube surfaces are optimized to the specific heat transfer requirement of the application. With a great variety of materials we ensure to use the material best suited to the specific needs, for example concerning durability and formability.

Our range of products

Our finned tubes at a glance.

Our complete product range

To show the product portfolio of a specific location, please select the company:

Enhanced surface tubes

Low-finned tubes

Medium-high finned tubes

High finned tubes

Safety tubes

Optimised heat transfer for your shell-and-tube heat exchanger

The enhanced surface tubes made by Wieland Thermal Solutions have been optimized for use as condenser or evaporator tubes in shell-and-tube heat exchangers used in the refrigeration and air-conditioning industry. These can be designed to be much more compact, saving you energy, installation space, and materials.

Your advantages at a glance

- Significantly higher heat transfer coefficients than smooth or low finned tubes

- More compact and lighter heat exchangers

- Significantly reduced filling quantities of e.g. refrigerants

- Highest efficiencies due to smallest temperature differences

- Precise thermal design with ThermalS

Optimized heat transfer for your shell-and-tube heat exchanger

The enhanced surface tubes made by Wieland Thermal Solutions have been optimized for use as condenser or evaporator tubes in shell-and-tube heat exchangers used in the refrigeration and air-conditioning industry. These can be designed to be much more compact, saving you energy, installation space and materials.

Materials

Thanks to their functional surface enhancements, the outsides of the GEWA-C and Turbo-C tubes offer optimal drainage performance for condensed refrigerants. Coupled with an ideally matched inner tube surface, optimum heat transfer coefficients can be achieved. GEWA and TURBO Condenser Tubes are available with outer and inner surfaces adapted for specific needs of your application.

GEWA

- C5 – For highest performance and efficiency

- C+SL/LW – For weight optimized alternatives as a "drop-in" solution

- CLF – For seawater & applications with increased fouling tendency

- CPL – For applications with high fouling tendency

TURBO

- C – The original condenser tube

- CSL – Efficient and lightweight

- CLF – For low fouling applications

- NCT – For large capacity chillers

- CPT – High efficiency in ferrous alloys

The functional enhancements of the outer surfaces of the GEWA-B, PB, and Turbo-B/E tubes have been optimized for bulk boiling of refrigerants and similar fluids. Coupled with ideally matched surfaces on the inside of the tubes, optimum heat transfer coefficients can be achieved. GEWA and TURBO Evaporator Tubes are available with outer and inner surfaces adapted for specific needs of your application.

GEWA

- B5 & B6 – For highest performance and efficiency

- B4HSL – For weight optimized alternatives as a "drop-in" solution

- BHV – For media with high viscosities

- BLF | BPL – For applications with high fouling tendency

TURBO

- B – The original boiling tube

- ESP – Efficient and lightweight

- EHPII – The industry standard boiling tube

- EPT – High efficiency in ferrous alloys

Our Materials

We offer you a broad portfolio of materials and can expand our offerings at any time to meet your specific needs regarding thermal conductivity, mechanical properties, or corrosion resistance. Enhanced surface tubes made by Wieland Thermal Solutions are already available in copper, copper-nickel, brass, carbon steel, stainless steel, and titanium.

You can find more product information here

For extreme efficiency in a variety of applications

Low-finned tubes are a reliable solution for controlling the temperature of gases and liquids, or for evaporating and condensing refrigerants. Thanks to their larger heat transfer surface area, they offer considerable potential to save in terms of materials and fill volumes. The wide range of dimensions offered by Wieland Thermal Solutions makes these products perfect for a broad scope of applications in the refrigeration and air conditioning industry, for oil/gas coolers in machinery and plant engineering, and for intermediate vapor superheaters in process engineering.

Your advantages at a glance

- Proven solution in a wide range of applications

- Increased heat transfer surface compared to plain tubes

- Material savings due to reduced tube length

- Filling quantity reduction due to higher efficiency

Materials

GEWA-K tubes offer a greater outer surface area compared to plain tubes. This is ideal for scenarios where the heat transfer surface coefficients vary significantly between the shell tube and the inner tube.

In GEWA-KS tubes, a special pattern is formed on the inside of the tube. This is ideal for scenarios with a low-heat transfer coefficient on the tube side, or an equally low-heat transfer coefficient on both sides.

Our Materials

We offer you a broad portfolio of materials and can expand our offering at any time to meet your specific needs regarding thermal conductivity, mechanical properties, or corrosion resistance. Low-finned tubes made by Wieland Thermal Solutions are already available in copper, copper-nickel, brass, carbon steel, stainless steel, and titanium.

You can find more product information here

GEWA-K/KS

S/T Trufin & TurboChil in Steel

S/T Trufin & TurboChil in Titanium

For compact coils and bent shapes

Medium-high finned tubes feature a significantly larger heat transfer surface area compared to plain tubes. They are ideal for compact and high-performance coils and shell-and-tube heat exchangers. Wieland medium-high finned tubes are a proven and robust solution for water heaters, storage tanks, refrigerant condensers, oil coolers, gas coolers or safety heat exchangers and more.

Your advantages at a glance

- High surface enlargement compared to plain tubes

- Ideal for compact and robust heat exchangers

- Excellent bending properties and processability

- Availability of various dimensions, internal structures and materials

Materials

GEWA-D finned tubes made of copper and copper alloys are available in a wide range of sizes and withstand the highest mechanical and thermic stress. They are specially made for the individual geometries of complex heat exchangers. Copper offers the highest heat conductivity of all technical metals. It is superior in processing, hygienic and a corrosion resistant solution.

GEWA-D finned tubes made of aluminium are specifically used in light-weight applications. Aluminium combines highest ductility with reasonable heat conductivity.

GEWA-D finned tubes made of carbon steel can be used in applications such as solid-fuel boilers or storage tanks. The significantly enlarged surface area compared to plain tubes allows compact solutions. Ready to install heat exchangers can be an interesting alternative solution for heat exchangers made of costly materials.

GEWA-D medium-high finned tubes made of stainless steel can be used for condensing boilers or domestic hot water applications. Due to the enlarged outside heat transfer surface area the required tube length can be reduced and thus costly material can be saved.

Our Materials

We offer the widest range of material in the industry and can extend it on request in case of special requirements for heat conductivity, mechanical properties or corrosion resistance. Medium-high finned tubes from Wieland Thermal Solutions are available in copper, copper-nickel, aluminium and carbon steel as well as in stainless steel in limited range.

You can find more information here

For highest efficiency in controlling the temperature of gases and liquids

High-finned tubes have a much greater outer surface area than smooth tubes. This allows for particularly compact designs. Thanks to their high, thin fins, these tubes perform particularly well in the heating and cooling of liquids and gases, making them an excellent choice for applications in heating technology, as well as in machinery and plant engineering.

Your advantages at a glance

- Highest surface enlargement compared to plain tubes (up to factor 18)

- Enables particularly compact and robust designs

- Available in straight lengths or as coiled heat exchanger

- Also available as bimetallic version GEWA-HB

Materials

GEWA-H tubes are available in a wide variety of sizes, either in straight sections or as coiled heat exchangers. They are primarily used as heat exchangers in gas boilers and as oil and gas coolers in applications related to machinery and plant engineering.

GEWA-HB tubes are high-finned tubes with a fixed inner tube made of a different material. This allows for more corrosion resistant (premium) materials to be used in combination with other, less expensive materials.

Our Materials

We offer you a broad portfolio of materials and can expand our offering at any time to meet your specific needs regarding thermal conductivity, mechanical properties, or corrosion resistance. High-finned GEWA-H tubes made by Wieland Thermal Solutions are already available in copper, copper-nickel and aluminum.

In the GEWA-HB tube materials like carbon steel, stainless steel, titanium or almost any other material like brass and nickel can be used for the inner tube.

You can find more information here

For absolutely reliable media separation with best thermal contact

Safety tubes are used for economical and safe heat transfer. The double wall tubes feature defined leakage paths for the absolutely reliable separation of fluids. For your individual requirements concerning fluid dynamics, we decide on the most suitable surface structure. Our GEWA-safe tubes are a reliable and safe choice for applications such as the direct heating of drinking water using critical fluids as in heating technology or for controlling the temperature of sensitive chemical processes.

GEWA-safe tubes are available in copper and copper alloys and provide safe drinking water heating in heat pumps, heat recovery systems, heat transfer stations and are used for transformer cooling.

Your advantages at a glance

- Reliable | Trust in reliable media separation through the double-tube system with defined leakage spaces.

- Efficient | Use direct and safe heat transfer of the media involved.

- Highest system availability | Detect leaks at an early stage and eliminate them during scheduled maintenance.

- Compact and economical | Reduce material costs and equipment requirements.

Our Materials

We offer you a broad portfolio of materials and can expand our offering at any time to meet your specific needs regarding thermal conductivity, mechanical properties, or corrosion resistance. GEWA-safe double wall tubes are available in copper and copper-nickel.

Read more

Heat exchanger for direct condensation in domestic hot water

Heat recovery from grey water

You can find more information here

Contact person

Get in touch - Our experts for finned tubes

![]() Andreas Moritz

Andreas Moritz

Heating Applications, Machinery & Plant Technology

Wieland-Werke AG

+49 731 944 1017

Send email

![]() Andreas Knoepfler

Andreas Knoepfler

Air Conditioning & Refrigeration, Process Technology

Wieland-Werke AG

+49 731 944 2892

Send email

Related topics

This might be of interest to you

Already know your search term? Then go ahead and use our full text search. You will get a list of all relevant results.