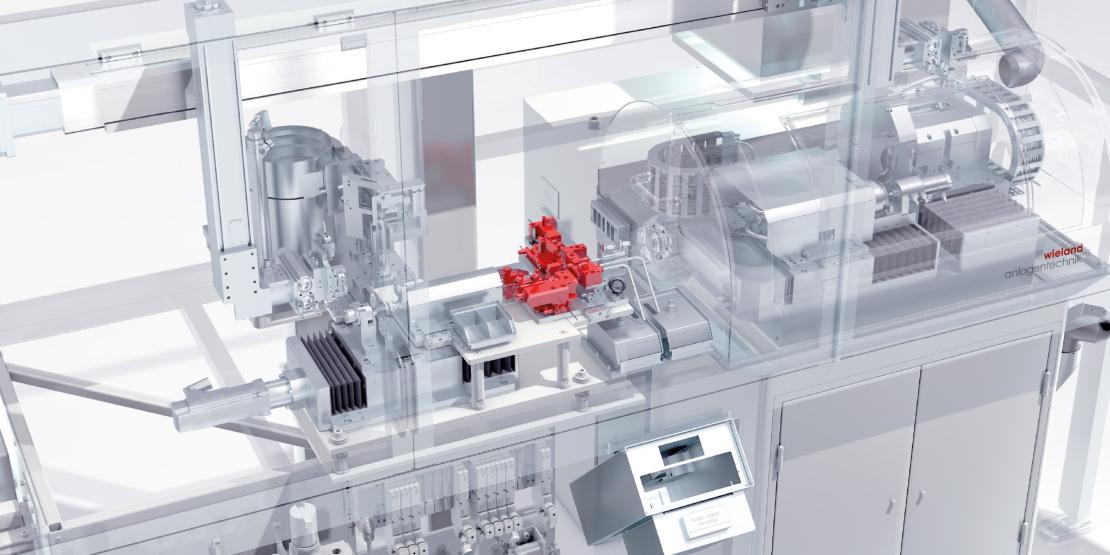

Grinding machines

For highest precision grinding.

We offer modular grinding machines for µ-accurate cylindrical and non-round grinding. Internal and external machining.

Our range of products

Our grinding machines at a glance.

Wieland Anlagentechnik

This is our Wieland Anlagentechnik product portfolio.

Contact person

Get in touch - Our experts for grinding machines

![]() Tobias Ziesel

Tobias Ziesel

Sales & Marketing

Wieland Anlagentechnik

+49 731 944 1822

Send email

Already know your search term? Then go ahead and use our full text search. You will get a list of all relevant results.